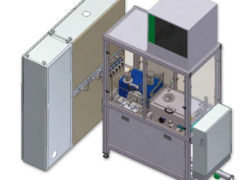

Multi-purpose thin film process system for functional coatings and treatment on wafer-like substrates

System description

The FHR.Star.220 is a cluster type system for wafer-based microelectronics, processing wafer-like substrates up to 100 mm (4 inches) diameter. The setup in the configuration shown consists of three connected vacuum chambers. The load lock chamber holds magazines with substrate carriers that are transferred to the process chamber via the handling chamber by means of a vacuum handler. The lid of the process chamber is equipped with a plasma pre-etching device and five compartments with RF (DC) planar sputter cathodes for 220 mm target diameter. The bottom is equipped with a rotatable substrate table on which up to 6 substrates can be loaded. The system can be operated in two modes of deposition. In static mode each of the 6 substrates substrate rests under a running sputtering source (thick layer, high deposition rate). In dynamic mode the substrate table with 6 substrates rotates and only one sputtering source is running (thin layer, low deposition rate). Any sequential series of pre-treatment and deposition of individual substrates can be carried out automatically according to the programmed process flow. Due to the flexibility and the possibility to achieve low and higher sputtering rates, the FHR.Star.220 product series is well suited for any advanced R&D and batch production in scientific and industrial environments.

Process

- Reactive and non-reactive magnetron sputtering (RF mode)

- Pre-treatment (e.g. plasma etching)

- Rotating substrate holder for 6 substrates

Benefits for the customer

- Maximum flexibility due to modular system concept

- Tailored configuration according to customer‘s needs

- Fully automatic process control

- Quick and easy target replacement

Key figures

Special features

- Rotating substrate holder for 6 substrates combined with substrate cooling

- Possibility to use diode sputtering to avoid thermal load on the substrate

- Clean room compatible with clean room wall

- Fully automated process control

- CE label

- Made in Germany

Options

- Customized magazine load lock system

Typical applications

- Functional coatings for MEMS and sensors

- Multilayered optical films

- Decorative coatings