General Description

To enable cost effective mass production in drying and curing of coatings on flexible substrates, Smit Ovens has developed a modular drying system.Inert dryer system

The design of the tool is such that it can be integrated in existing R2R applications. The design is based on a wide flexible substrate which is transported by a roll to roll handling system.

The flexible substrate is heated from both top and bottom: the top by convection and bottom by radiation. The drying system will mix fresh air with re-circulated air, heat up the air by radiant heaters and supply it to the process area. Below the substrate an additional radiant heating system is installed which attributes to control the atmosphere temperature below the web very accurate. Both the temperature and the convective airflow are adjustable.

An exhaust system extracts the process gasses from the system. The pressure inside the system can be influenced by changing the ratio between the supply flow and the exhaust flow.

Typical Process

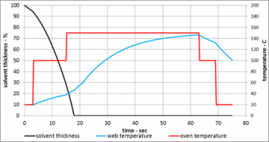

Typically the process contains a number of thermal process steps allowing the coated layers to dry and, cure. The graph below shows the result of a simulation and describes a typical temperature profile which enables successful drying and curing of a coated flexible substrate.